The Beta configuration is the classic Stirling engine configuration and has enjoyed popularity from its inception until today. Stirling's original engine from his patent drawing of 1816 shows a Beta arrangement. A photograph of Robert Stirling, the original patent drawing, as well as an animated model of Stirling's engine is clearly shown in an interesting website by Robert Sier. From the figure below we see that unlike the Alpha machine, the Beta engine has a single power piston and a displacer, whose ideal purpose is to "displace" the working gas at constant volume, and shuttle it between the expansion and the compression spaces through the series arrangement cooler, regenerator, and heater. In actual engines the linkage driving the piston and displacer will move them such that the gas will compress while it is mainly in the cool compression space and expand while in the hot expansion space. This is clearly illustrated in the adjacent animation which was produced by Richard Wheeler ( Zephyris) of Wikipedia.

|

|

|

A detailed description of the ideal Beta machine cycle is presented in the Engineering Thermodynamics - Chapter 3b web resource. Refer also to the animation of the Beta machine by Matt Keveney - Single Cylinder Stirling Engine, showing clearly the principle of operation.

Apart from Stirling's original engine, an important early Beta engine is Lehmann's machine on which Gustav Schmidt did the first reasonable analysis of Stirling engines in 1871. Andy Ross built a small working replica of the Lehmann machine, as well as a model air engine, both based on single cylinder Beta configurations.

Rolf Meijer of Philips, Holland, developed his famousnvibrationless rhombic drive Beta engines in the early 1960s. In 1965 the General Motors Research Labs developed a 7.5kW rhombic drive Stirling engine/generator set GPU-3 (Ground Power Unit) for the US Army. It is described and analyzed in the book by I.Urieli & D.M.Berchowitz – Stirling Cycle Engine Analysis (Adam Hilger, 1984), pages 30 – 40, and since this book is out of print, these pages have been added here for convenience: Rhombic-GPU-3.pdf. Andy Ross built a few small rhombic drive air engines – refer to his book: Making Stirling Engines (Ross Experimental, 1993).

Another interesting website is Stirling Engine Boats by Andrew Hall describing boats powered mainly by Beta type engines built by modelers in the United Kingdom.

Free Piston Stirling Engines

Probably the most ingenious Stirling engines yet

devised are the free-piston engines invented and developed by William

Beale at Ohio University in the late

1960s. Legend has it that while teaching about the rhombic drive

engine he suddenly realized that "this engine will still run if

we simply throw away this

complex drive mechanism - Eureka!". He then formed the company

Sunpower,

which has been the leader in the development of free-piston Stirling

engines and cryocoolers to this day.

Most of Sunpower's engines are Beta arrangements and

employ no mechanical linkage system. The main aspect of the free

piston machine is that the output power can be obtained through a

linear alternator, allowing the entire system to be hermetically

sealed. In fact, this is the only Stirling configuration to reach

commercialization in any numbers. This is mainly because it avoids

the fatal flaws of the crank, proven again and again over the years

to be near-insurmountable - sealing and lubrication.

Since

1974 Sunpower

has developed Free Piston Stirling Engine/Generators

ranging in power levels from 35We

to 7.5kWe.

Consider for example the EG-1000 engine/generator which is gas fired

and has been designed to generate electricity (1kWe)

as well as to provide hot water for a private home. The working gas

used is helium, which has the advantage of having a low molecular

weight and high thermal conductivity compared to air, allowing a

significant reduction in size. This engine is shown in the figure

below together with a simplified schematic diagram.

|

|

The linear electrical generator (not shown in the above schematic) is comprised of powerful rare-earth magnets in the piston cutting a magnetic circuit and coils in the cylinder. This produces 240 Volts at 50 Herz - designed for operation in Europe, and is capable of producing more than one kilowatt of electrical power output at an efficiency of around 90%.

|

The Sunpower EG-1000 free-piston Stirling engine/generator

|

|

In this photograph we see the Sunpower EG-1000 being demonstrated using sawdust pellets as the fuel, and generating more than 1000W of electricity to a light panel. This was done at the Sustainability Fair in the Fairgrounds of Athens Ohio, 2001. A closeup photograph of the basic system is shown. Notice the closed cycle radiator and vibration pump used in the water cooling system. |

Note that since 1995 the

EG-1000 technology was used by British Gas to develop CHP (Combined

Heat and Power) units – the 1kW engine/generator is currently

manufactured by Microgen

Engine Corporation (refer

to their History

and Engine

web pages).

An

extremely interesting free piston engine system developed by William

Beale is the free-cylinder

water pump. In this engine a heavy

internal mass provides the reaction force driving the cylinder which

is directly connected to the water pump. It has built in power

adjustment and responds to load automatically. All other engines

require a transmission and complicated control mechanisms to do this.

Furthermore, there is no other mechanical heat engine that I know of

that operates from infinite load to zero without either stalling or

destroying itself.

Another attractive feature of the free

cylinder system is that it can be constructed from inexpensive

easy-to-obtain components. In fact, the entire pump housing can be

fabricated from ordinary PVC piping and fixtures. The reliability,

simplicity and low cost of this engine makes it eminently suitable

for application in developing countries, and in the 1970's it was

extensively tested both in the field and in the laboratory (Refer to

the 1979 presentation by William Beale A

Free-Cylinder Stirling Engine for Solar Powered Water Pumps).

Two interesting free piston Stirling powered refrigeration systems have also been investigated – a duplex gas fired refrigerator having only three moving parts, one power piston and two displacer pistons (refer to the paper by L.B.Penswick & I.Urieli – Duplex Stirling Machines (I. Energy Conversion Engineering Conference, 1984), and a gas fired free piston CO2 refrigeration system (refer to the paper by D.M.Berchowitz & Yong-Rak Kwan – Hermetic Gas Fired Residential Heat Pump).

Sunpower was also involved in the manufacture of Stirling cycle cryogenic coolers for liquifying oxygen. Over the years Sunpower has transformed Athens, Ohio into a hotbed of Stirling cycle machine activity, which now includes three R&D/manufacturing companies. In 2013 Sunpower was acquired by AMETEK, Inc in Pensylvania, however continues doing Stirling cycle machine development in Athens, Ohio. Chapter 3 of the book by I.Urieli and D.M.Berchowitz – Stirling Cycle Engine Analysis (Adam Hilger 1984), is entirely about the analysis of Free-Piston machines, and since this book is out of print, this chapter has been added here in four parts for convenience: Free-Piston(1).pdf, Free-Piston(2).pdf, Free-Piston(3).pdf, Free-Piston(4).pdf. Refer also to the paper by R.W.Redlich & D.M.Berchowitz – Linear dynamics of free-piston Stirling engines (ImechE 1985), and to the Lecture Notes in Engineering by G.Walker & J.R.Senft – Free Piston Stirling Engines (Springer-Verlag 1985, currently available as an eBook).

An interesting paper describing the chronology of the development of Free Piston Stirling engine technology was presented by David Berchowitz at the 2018 International Stirling Engine Conference (Refer: A Personal History in the Development of the Modern Stirling Engine).

The NASA Glenn Research Center has been involved in developing free-piston Stirling Engines for deep space missions since the mid-1970's. One of their experimental units has recently set a run time record of more than 110,000 hours, running constantly at full power since 2003, and still running without any signs of performance degradation. More recently they have been concentrating on the Kilopower Reactor Using Stirling TechnologY (KRUSTY) for up to 10kW power – refer also to the National Nuclear Security Administration and their youtube video.

Stirling

Technology (note recent company name

change: Combined Energy

Technology) is a spinoff of Sunpower,

and was originally formed in order to continue the development and

manufacture of the 3.5 kW ST-5

Air engine. This large Beta type engine

uses a bell crank mechanism to obtain the correct displacer phasing,

burns biomass fuel (such as sawdust pellets or rice husks), and can

function as a cogeneration unit in rural areas.

Currently

Stirling Technology is working with Microgen

Engine Corporation, an international

company which produces the MEC 1kW free-piston engine/generator.

Stirling Technology has developed a multifuel burner for the engine

and is partnering with Microgen to get various systems into the

market.

Global Cooling (currently Stirling Ultracold) was a spinoff from Sunpower and was formed in 1995 by David Berchowitz mainly in order to develop free-piston Stirling cycle coolers for home refrigerator applications. These systems, apart from being significantly more efficient than regular vapor-compression refrigerators, have the added advantage of being compact, portable units using helium as the working fluid (and not the HFC refrigerants such as R134a, having a Global Warming Potential of 1,300). A schematic diagram followed by an animated schematic of a typical cooler (both courtesy of Global Cooling) are shown below:

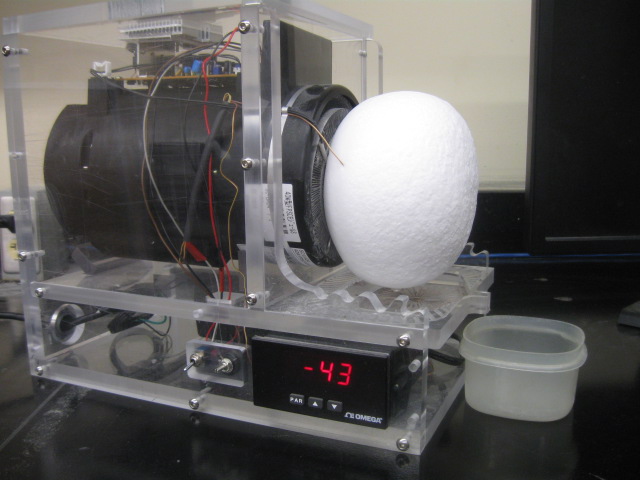

At Ohio University we have a demonstration Global Cooling Stirling Cooler shown below. It will normally reach -90°C, however since the ball of ice is covering the entire regenerator section we notice that the temperature has risen to -43°C.

More recently Global Cooling decided to concentrate

their development efforts on systems in which there are virtually no

competitive systems - cooling between -40°C and -80°C, and they

established a new company name: Stirling

Ultracold.

Update

- 2021: Stirling

Ultracold's Ultra-Low Temperature (ULT)

freezers meet today's unprecedented COVID-19 deployment challenges.

Refer to Walgreens

COVID-19 Vaccine Case Study as well as

Stirling

Ultracold to Merge with Biolife Solutions.

______________________________________________________________________________________

![]()

Stirling Cycle Machine Analysis by Israel

Urieli is licensed under a Creative

Commons Attribution-Noncommercial-Share Alike 3.0 United States

License