The mechanical configurations of Stirling engines are generally divided into three groups known as the Alpha, Beta, and Gamma arrangements. Alpha engines have two pistons in separate cylinders which are connected in series by a heater, regenerator and cooler. Both Beta and Gamma engines use displacer-piston arrangements, the Beta engine having both the displacer and the piston in an in-line cylinder system, whilst the Gamma engine uses separate cylinders.

The Alpha engine is conceptually the simplest Stirling engine configuration, however suffers from the disadvantage that both the hot and cold pistons need to have seals to contain the working gas. There are a number of mechanical mechanisms which enable this type of engine to operate correctly with the correct phasing of the two pistons. An excellent animation of the V-type Alpha engine developed by Richard Wheeler (Zephyris) of Wikipedia is shown below:

Andy Ross of Columbus, Ohio has been designing and building small air engines since the 1970's, including extremely innovative Alpha designs. He is the inventor of the classical Ross Yoke drive engine as well as a balanced “Rocker-V” mechanism, both shown below.

Refer to Andy Ross' delightful book: Making Stirling Engines (Ross Experimental, 1993). The D-90 Yoke drive Alpha Stirling engine described in his book will be used as the primary case study of this web resource. At Ohio University we have a laboratory model of the D-90 Yoke drive engine which is heated electrically in order to accurately determine the heat power input. Matt Keveney has done an animation showing clearly the principles of operation of the Ross yoke linkage mechanism. This ingenious mechanism for transferring dual piston motion into rotational motion minimizes the piston side forces normally encountered on a regular crankshaft mechanism.

More recently Andy Ross came up with the balanced Rocker-V mechanism design. He has published an article on the model Climax locomotive that he built using a small (20cc) Rocker-V engine, and allowed me to maintain a copy of this article "A Class A Climax Locomotive". A number of these Rocker-V engines were built by students for a Senior Design class at Ohio University in 2001, and will also be used as a case study of this web resource. One of Andy Ross' many "youtube" videos shows a unique balanced double-V Alpha engine which avoids the use of a heat exchanger section stretching across the V.

Cool Energy, Inc of Boulder, Colorado have been developing low temperature (150°C – 400°C) Alpha Stirling engine/generator systems since 2006 (Refer to their Product Development History). This included a complete solar heat and power cogeneration system for home usage including evacuated tube solar thermal collectors, thermal storage systems, hot water and space heaters, and the SolarHeart Stirling engine/generator. Currently they are concentrating on waste heat recovery systems (Refer: Cool Energy ThermoHeart 25kW Engine Overview) using the four cylinder Alpha engine as described in the paper presented at the 2016 International Stirling Engine Conference by the Cool Energy team: 25kW Low Temperature Stirling Engine for Heat Recovery, Solar, and Biomass Applications).

Multiple Cylinder Alpha Stirling Engines

The Alpha engine can also be compounded into a compact multiple cylinder configuration, enabling an extremely high specific power output. A schematic diagram of this configuration is shown below. Notice that the four cylinders are interconnected, so that the expansion space of one cylinder is connected to the compression space of the adjacent cylinder via a series connected heater, regenerator and cooler. The pistons are typically driven by a swashplate, resulting in a pure sinusoidal reciprocating motion having a 90 degree phase difference between the adjacent pistons.

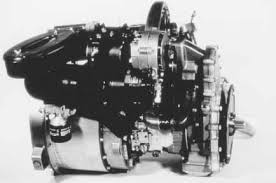

One example of the swashplate 4-cylinder Alpha engine is shown below. This engine was originally developed by Stirling Thermal Motors (later STM Corporation, however is no longer operational).

During

the 1970's N V Philips, of Holland, and the Ford Motor Company

developed an experimental automotive engine – a four-cylinder

swashplate-drive engine as shown in the following photograph:

This

engine, the Ford-Philips 4-215 engine, is used as a case study in the

book by I.Urieli & D.M.Berchowitz – Stirling Cycle Engine

Analysis (Adam Hilger, 1984), pages 25 – 31. It will be one of the

case studies of this learning resource, and since the book is out of

print, these pages have been added here for convenience:

Ford-Philips.pdf.

William Beale of Sunpower, Inc came up with an interesting configuration, combining a four cylinder free-piston alpha engine with a gas turbine output stage, as shown in the following schematic diagram:

The four cylinders are physically arranged with a 90 degree phase difference with each piston connected to a gas compressor. The gas compressors are then used to drive a gas turbine expander as shown. The main advantage of this system is the promise of a high specific power and most important, high reliability and life resulting from the absence of heavily loaded moving parts, since there are no side loads on any sliding bearings.

The sketch shows single acting gas compressors for simplicity, however the actual machine would use double acting compressors so that there are eight gas pulses on the turbine for each cycle of the four cylinder machine.

______________________________________________________________________________________

![]()

Stirling Cycle Machine Analysis by

Israel

Urieli is licensed under a Creative

Commons Attribution-Noncommercial-Share Alike 3.0 United States

License