From the 1950's through the 1980's there was an ambitious effort to develop automobile Stirling engines in the USA and Europe (refer to NASA publications on the Ford Motor Company program and the Mechanical Technology Inc. (MTI) program.)

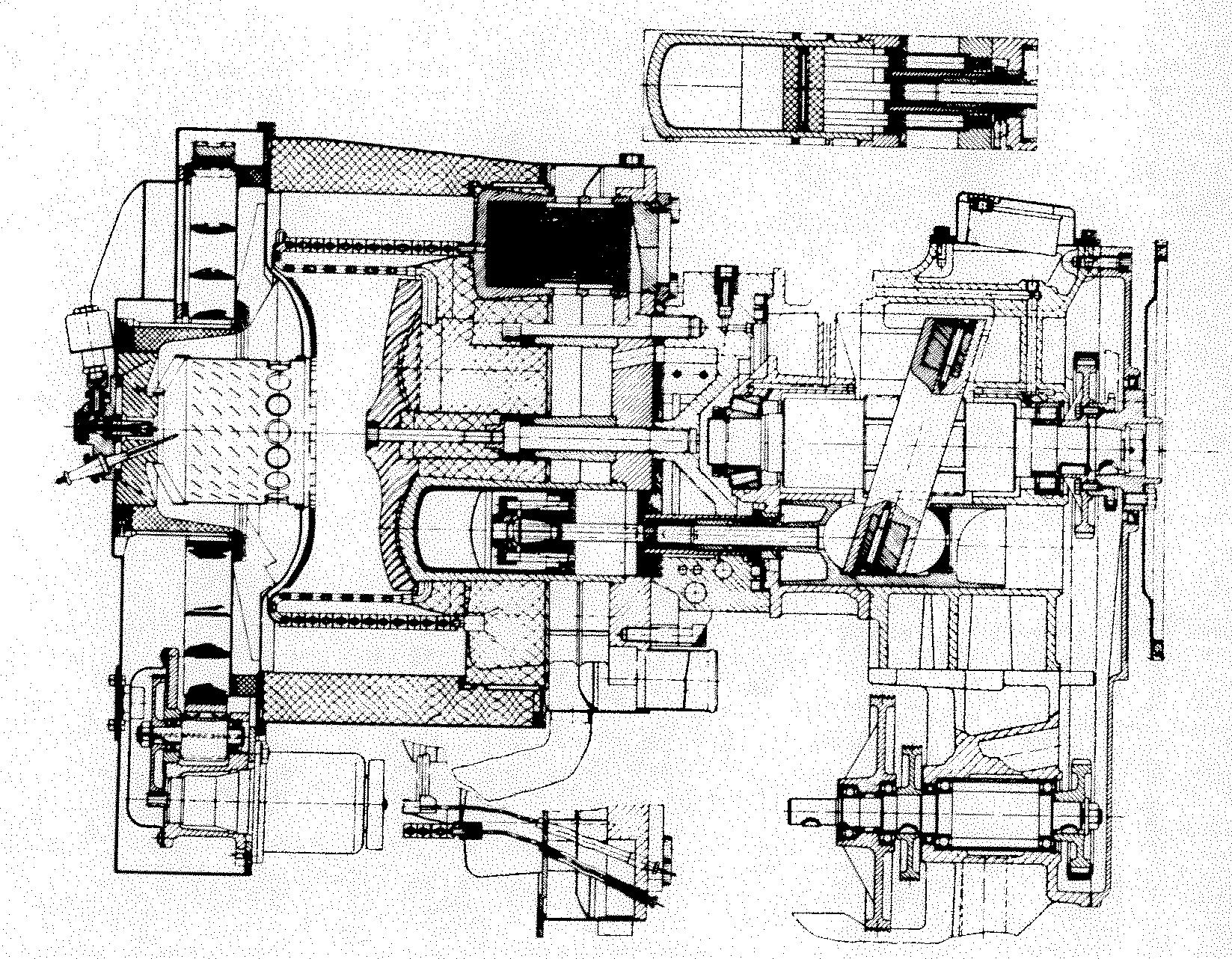

During the 1970's N V Philips, of Holland, and the Ford Motor Company developed the Ford-Philips 4-215 engine – a four-cylinder swashplate-drive engine as shown below:

|

|

|

This engine was used as a case study in the book by I.Urieli & D.M.Berchowitz – Stirling Cycle Engine Analysis (Adam Hilger, 1984), pages 25 – 31, and since the book is out of print, these pages have been added here for convenience: Ford-Philips.pdf. All the required data for the simulation is available from this file.

The swashplate drive is a pure sinusoidal motion, and with four pistons the volumetric phase angle advance is 90 degrees. Thus the global variables data required is simply entered from the keyboard to create a data file, or read from a previously created data file, and no calculations are required. The MATLAB function sindrive follows:

function sindrive

% Sinusoidal drive engine configuration

% Israel Urieli 4/14/02

global vclc vcle % compression, expansion clearance vols [m^3]

global vswc vswe % compression, expansion swept volumes [m^3]

global alpha % phase angle advance of expansion space [radians]

global new fid % new data file

fprintf('sinusoidal drive engine configuration\n');

if(strncmp(new,'y',1))

vclc = input('enter compression space clearance volume [m^3]: ');

vswc = input('enter compression space swept volume [m^3]: ');

vcle = input('enter expansion space clearance volume [m^3]: ');

vswe = input('enter expansion space swept volume [m^3]: ');

phase = input('enter expansion phase angle advance [degrees]: ');

fprintf(fid, '%.3e\n', vclc);

fprintf(fid, '%.3e\n', vswc);

fprintf(fid, '%.3e\n', vcle);

fprintf(fid, '%.3e\n', vswe);

fprintf(fid, '%.1f\n', phase);

else

vclc = fscanf(fid, '%e', 1);

vswc = fscanf(fid, '%e', 1);

vcle = fscanf(fid, '%e', 1);

vswe = fscanf(fid, '%e', 1);

phase = fscanf(fid, '%f', 1);

end

fprintf('\nsinusoidal drive engine data summary:\n');

fprintf('comp clearance,swept vols %.1f, %.1f [cm^3]\n', vclc*1e6, vswc*1e6);

fprintf('exp clearance,swept vols %.1f, %.1f [cm^3]\n', vcle*1e6, vswe*1e6);

fprintf('expansion phase angle advance %.1f[degrees]\n', phase);

alpha = phase * pi/180;

%==============================================================

|

Notice that the main purpose of this function is to fill in values of the global variables concerning the working space (compression and expansion) volumes. The remaining global variables are concerning the heat exchangers, regenerator, working gas and operating conditions are determined in the various functions of the define function set.

|

At Ohio University we have one of the four pistons and one of the eight cooler heat exchanger and mesh regenerator tubes of the Ford-Philips 4-215 engine. The engine has a total of 2968 cooler tubes with a 0.9mm internal diameter and 87mm length, and extremely fine wire diameter regenerator mesh (36µm) leading to more than 100 square meters of wetted area. This indicates the extreme importance of the heat exchanger section of the engine which we will cover in the Chapter 5 of this learning resource.

|

|

The rest of the define function modules include the heat exchangers, regenerator, operating parameters, working gas parameters and Schmidt analysis, and all are independent of the engine type. The complete data file that defines the Ford-Philips 4-215 engine is ford.dat.

______________________________________________________________________________________

![]()

Stirling Cycle

Machine Analysis by Israel

Urieli is licensed under a Creative

Commons Attribution-Noncommercial-Share Alike 3.0 United States

License