Chapter 3: The First Law of Thermodynamics for

Closed Systems

b) Ideal Stirling Cycle Machines (Engines /

Coolers)

1. The Stirling Cycle Engine

Conceptually the Stirling engine is the simplest of

all heat engines. It has no valves, and includes an externally heated

space and an externally cooled space. It was invented by Robert

Stirling, and an interesting website by Bob

Sier includes a photograph of Robert

Stirling, his original patent drawing of 1816, and an animated model

of Stirling's original engine.

|

In its original single cylinder form the working

gas (typically air or helium) is sealed within its cylinders by

the piston and shuttled between the hot and cold spaces by a

displacer. The linkage driving the piston and displacer will move

them such that the gas will compress while it is mainly in the

cool compression space and expand while in the hot expansion

space. This is clearly illustrated in the adjacent animation which

was produced by Richard Wheeler (Zephyris)

of Wikipedia.

Refer also to the animation produced by Matt

Keveney in his Stirling

engine animation website. Since the

gas is at a higher temperature, and therefore pressure, during its

expansion than during its compression, more power is produced

during expansion than is reabsorbed during compression, and this

net excess power is the useful output of the engine. Note that

there are no valves or intermittent combustion, which is the major

source of noise in an internal combustion engine. The same working

gas is used over and over again, making the Stirling engine a

sealed, closed cycle system. All that is added to the system is

steady high temperature heat, and all that is removed from the

system is low temperature (waste) heat and mechanical power.

|

|

Athens, Ohio, is a hotbed of Stirling cycle machine

activity, both engines and coolers, and includes R&D and

manufacturing companies as well as internationally recognized

consultants in the area of Stirling cycle computer analysis. The

parent company of this activity is Sunpower.

It was formed by William

Beale in 1974, mainly based on his

invention of the free-piston Stirling engine which we describe below.

They developed a 1kW free-piston engine/generator, and since 1995

this technology was used by British Gas to develop CHP (Combined Heat

and Power) units – the 1kW engine/generator is currently

manufactured by Microgen

Engine Corporation (refer to their

History

and Engine

web pages).

In 2013 Sunpower was acquired by Ametek

in Pensylvania, however continues doing Stirling cycle

machine development in Athens, Ohio.

Some examples of single cylinder Stirling engines:

Stirling

Technology (note recent company name

change: Combined Energy

Technology) is a spinoff of Sunpower,

and was originally formed in order to continue the development and

manufacture of the 3.5 kW ST-5

Air engine. This large single cylinder

engine burns biomass fuel (such as sawdust pellets or rice husks) and

can function as a cogeneration unit in rural areas. It is not a

free-piston engine, and uses a bell crank mechanism to obtain the

correct displacer phasing.

Currently Combined Energy Technology

is working with Microgen

Engine Corporation, an international

company which produces the MEC 1kW free-piston engine/generator.

Combined Energy Technology has developed a multifuel burner for the

engine and is partnering with Microgen to get various systems into

the market.

Another important early Stirling engine is Lehmann's

machine on which Gustav Schmidt did the first reasonable analysis of

Stirling engines in 1871. Andy Ross of Columbus, Ohio built a small

working replica of the Lehmann

machine, as well as a model

air engine.

Solar Heat and Power Cogeneration: With

the current energy and global warming crises, there is renewed

interest in renewable energy systems, such as wind and solar energy,

and distributed heat and power cogeneration systems. Cool

Energy of Boulder, Colorado, previously

developed a complete solar

heat and power cogeneration system for

home usage incorporating Stirling engine technology for electricity

generation. This unique application included evacuated

tube solar thermal collectors (slide

courtesy of rusticresource.com),

thermal storage, hot water and space heaters, and a Stirling

engine/generator using nitrogen gas. Currently they are concentrating

on low temperature (150°C - 400°C) waste heat recovery systems

(Refer: Cool

Energy ThermoHeart 25kW Engine Overview).

Ideal Analysis: Please

note that the following analysis of

Stirling cycle engines is ideal, and is intended only as an example

of First Law Analysis

of closed systems. In the real world we cannot expect

actual machines to perform any better than 40 - 50% of the ideal

machine. The analysis of actual Stirling cycle machines is extremely

complex and requires sophisticated computer analysis (see for example

the web learning resource on: Stirling

Cycle Machine Analysis.)

The free-piston Stirling engine developed by

Sunpower, Inc is unique in that there is no mechanical connection

between the piston and the displacer, thus the correct phasing

between them occurs by use of gas pressure and spring forces.

Electrical power is removed from the engine by permanent magnets

attached to the piston driving a linear alternator. Basically the

ideal Stirling engine undergoes 4 distinct processes, each one of

which can be separately analysed, as shown in the P-V diagram

below. We consider first the work done during all four processes.

Process 1-2 is the compression process in which

the gas is compressed by the piston while the displacer is at the

top of the cylinder. Thus during this process the gas is cooled in

order to maintain a constant temperature TC.

Work W1-2 required

to compress the gas is shown as the area under the P-V

curve, and is evaluated as follows.

Process 2-3 is a

constant volume displacement process in which the gas is displaced

from the cold space to the hot expansion space. No work is done,

however as we shall see below, a significant amount of heat QR

is absorbed by the gas from the regenerator matrix.

Process 3-4 is the isothermal expansion process.

Work W3-4 is done

by the system and is shown as the area under the P-V

diagram, while heat Q3-4

is added to the system from the heat source,

maintaining the gas at a constant temperature TH.

The net work Wnet

done over the cycle is given by: Wnet

= (W3-4 +

W1-2), where the

compression work W1-2 is

negative (work done on the

system).

We now consider the heat transferred during all four

processes, which will allow us to evaluate the thermal efficiency of

the ideal Stirling engine. Recall from the previous section that in

order to do a First Law analysis of an ideal gas to determine the

heat transferred we needed to develop equations to determine the

internal energy change Δu in terms of the Specific

Heat Capacities of an Ideal Gas.

The two constant volume processes are formed by

holding the piston in a fixed position, and shuttling the gas between

the hot and cold spaces by means of the displacer. During process 4-1

the hot gas gives up its heat QR

by passing through a regenerator matrix, which is

subsequently completely recovered during the process 2-3.

We will find in Chapter

5 that this is the maximum theoretical

efficiency that is achievable from a heat engine, and usually

referred to as the Carnot

efficiency. For more information on this subject, refer

to a paper: A

Meeting between Robert Stirling and Sadi Carnot in 1824

presented at the 2014

ISEC.

Note that if no regenerator is present the heat QR

must be supplied by the heater. Thus the efficiency will

be significantly reduced to ηth

= Wnet /

(Qin + QR).

Furthermore the cooler will then have to reject the heat that is

normally absorbed by the regenerator, thus the cooling load will be

increased to Qout +

QR. Recall that

Q2-3 = QR

= -Q4-1.

Note that the practical Stirling cycle has many losses

associated with it and does not really involve isothermal processes,

nor ideal regeneration. Furthermore since the Free-Piston Stirling

cycle machines involve sinusoidal motion, the P-V

diagram has an oval shape, rather than the sharp edges

defined in the above diagrams. Nevertheless we use the ideal Stirling

cycle to get an initial understanding and appreciation of the cycle

performance.

Problem

3.2 - The Sunpower EG-1000 Stirling

Engine/Generator

___________________________________________________________________

2. The Stirling Cycle Cooler

One important aspect of Stirling cycle machines that

we need to consider is that the cycle can be reversed - if we put net

work into the cycle then it can be used to pump heat from a low

temperature source to a high temperature sink. Sunpower

has been actively involved in the deveplopment of

Stirling cycle refrigeration systems and produces Stirling cycle

croygenic coolers for liquifying oxygen. In 1984 Sunpower developed a

free piston Duplex

Stirling Machine having only three moving

parts including one piston and two displacers, in which a gas fired

Stirling cycle engine powered a Stirling cycle cooler. Global Cooling

was established in 1995 as a spinoff of Sunpower, and

was formed mainly in order to develop free-piston Stirling cycle

coolers for home refrigerator applications. These systems, apart from

being significantly more efficient than regular vapor-compression

refrigerators, have the added advantage of being compact, portable

units using helium as the working fluid (and not the HFC refrigerants

such as R134a, having a Global Warming Potential of 1,300). More

recently Global Cooling decided to concentrate their development

efforts on systems in which there are virtually no competitive

systems - cooling between -40°C and -80°C, and they established a

new company name: Stirling

Ultracold.

Update

- 2021: Stirling

Ultracold's Ultra-Low Temperature (ULT)

freezers meets today's unprecedented COVID-19 deployment challenges.

Refer to Walgreens

COVID-19 Vaccine Case Study as well as

Stirling

Ultracold to Merge with Biolife Solutions.

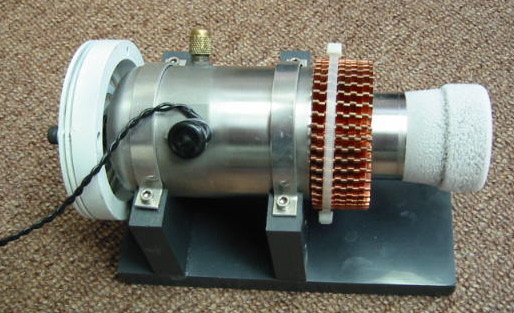

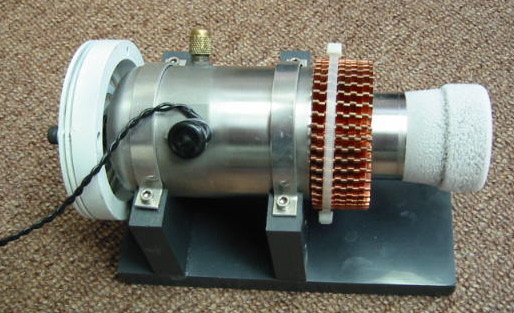

We are fortunate to have obtained two original M100B

coolers from Global Cooling. The one is used as a demonstrator unit,

and is shown in operation in the following photograph. The second

unit is set up as a ME Senior

Lab project in which we evaluate the

actual performance of the machine under various specified loads and

temperatures.

A schematic diagram followed by an animated schematic

of the cooler (both courtesy of Global Cooling (currently Stirling

Ultracold) are shown below

Conceptually the cooler is an extremely simple

device, consisting essentially of only two moving parts - a piston

and a displacer. The displacer shuttles the working gas (helium)

between the compression and expansion spaces. The phasing between the

piston and displacer is such that when the most of the gas is in the

ambient compression space then the piston compresses the gas while

rejecting heat to the ambient. The displacer then displaces the gas

through the regenerator to the cold expansion space, and then both

displacer and piston allow the gas to expand in this space while

absorbing heat at a low temperature.

______________________________________________________________________________________

Problem 3.3 - Stirling Cycle

Cooler M100B - Ideal Analysis

Unfortunately the analysis of actual Stirling cycle

machines is extremely complex and requires sophisticated computer

analysis. We consider the idealised model of this cooler defined in

terms of the P-V diagram

shown below in order to determine the ideal performance of the M100B

under typical operating conditions as described below. (Note

that the values presented here are not actual values of the M100B,

however were devised by your instructor for purposes of this exercise

only).

Process (1)-(2) is the isothermal compression process

at temperature TC =

30°C, during which heat QC is

rejected to the ambient. Process (2)-(3) is the constant volume

displacement process during which heat QR

is rejected to the regenerator matrix. Process (3)-(4)

is the isothermal expansion process at temperature TE

= -20°C,

during which heat QE is

absorbed from the freezer, and finally process (4)-(1) is the

constant volume displacement process during which heat QR

is absorbed from the regenerator matrix. Thus the ideal

Stirling cycle consists of four distinct processes, each one of which

can be separately analysed. State (1) is defined at a maximum volume

of 35 cm3 and a

pressure of 1.9 MPa, and State (2) is defined at a minimum volume of

30 cm3. The energy

transferred during both the compression and expansion processes is

indicated on P-V diagrams

as follows:

Since the working fluid is helium which is an ideal

gas, we use the ideal gas equation of state throughout. Thus P V = m

R T, where R = 2.077 kJ/kg K, and Δu = Cv ΔT, where Cv = 3.116

kJ/kg K. (refer: Ideal

Gas Properties)

a) Determine the heat absorbed in the expansion

space QE during

the expansion process (3) - (4) (Joules). Determine also the heat

power absorbed (Watts). Note that the cycle frequency is the line

frequency (f = 60 Hz). [QE

= 8.56J (power = 513.6W)]

b) Determine the net work done per cycle

(Joules): Wnet =

WE + WC

(Note that the compression work WC

is always negative). Determine also the power supplied

to the linear electric motor (Watts). [Wnet

= -1.69J (power = -101W)]

c) Evaluate the Coefficient of Performance of

the refrigerator defined as: COPR

= QE /

Wnet. (heat

absorbed in the expansion space divided by the net work done). [COPR

= 5.07]

d) Determine the amount of heat rejected by the

working fluid QR as

it passes through the regenerator matrix during process (2) - (3).

[QR

= -16.46J (power = -988

W)]

If there were no regenerator

present then this heat would need to be removed from the gas by the

expansion process in order to reduce the temperature to the cold

temperature of the freezer. How would this affect the performance of

the cooler? Discuss the importance of an effective regenerator in

the Stirling cycle cooler.

______________________________________________________________________________________

______________________________________________________________________________________

Engineering Thermodynamics by Israel

Urieli is licensed under a Creative

Commons Attribution-Noncommercial-Share Alike 3.0 United States

License