Problem 3.2 - The Sunpower EG-1000

Stirling Engine/Generator

Since 1974 Sunpower,

Inc has developed Free Piston Stirling

Engine/Generators ranging in power levels from 35We

to 7.5kWe.

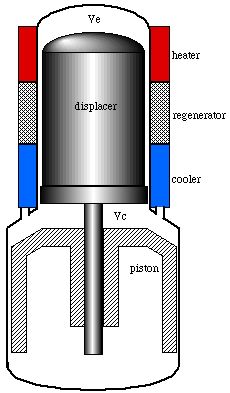

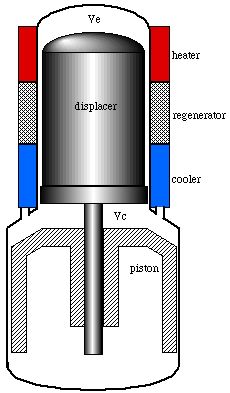

This exercise concerns the ideal performance of the EG-1000 Stirling

engine which is gas fired and was designed to generate electricity

(1kWe) as well as

to provide hot water for a private home. This engine is shown in the

figure below together with a simplified schematic diagram. Notice

that there are two pistons - a power piston which allows compression

and expansion of the working gas (helium) and a displacer piston

which shuttles the working gas between the hot expansion space VE

and the cold compression space VC,

through the series connected heater, regenerator and cooler.

Conceptually the Stirling engine is the simplest of all heat engines.

The working gas is sealed within its cylinder by the power piston.

The displacer piston shuttles the gas such that the gas will compress

while it is mainly in the cool compression space and expand while in

the hot expansion space. Since the gas is at a higher temperature,

and therefore pressure, during its expansion than during its

compression, more power is produced during expansion than is

reabsorbed during compression, and this net excess power is the

useful output of the engine. Note that there are no valves or

intermittent combustion, which is the major source of noise in an

internal combustion engine. The same working gas is used over and

over again, making the Stirling engine a sealed, closed cycle system.

All that is added to the system is steady high temperature heat, and

all that is removed from the system is low temperature heat and

mechanical power.

|

|

The linear electrical generator (not shown in the

above schematic) is comprised of powerful rare-earth magnets in

the piston cutting a magnetic circuit and coils in the cylinder.

This produces 240 Volts at 50 Herz - designed for operation in

Europe, and is capable of producing more than one kilowatt of

electrical power output at an efficiency of around 90%.

Note:

The hot water is provided by operating the cooling water at a

temperature of 50°C.

|

Figure 1 -

The Sunpower EG-1000 free-piston Stirling engine/generator

Note that since 1995 the

EG-1000 technology was used by British Gas to develop CHP (Combined

Heat and Power) units – the 1kW engine/generator is currently

manufactured by Microgen

Engine Corporation (refer

to their History

and Engine

web pages).

Unfortunately

the analysis of actual Stirling cycle machines is extremely complex

and requires sophisticated computer analysis, mainly due to the

non-steady convective heat transfer processes. We consider an

idealized model of this engine defined in terms of the P-V

diagram shown below, and will attempt to quantify the

performance characteristics from this ideal model. These are the

mechanical output power, the thermal efficiency, thermal power for

home water heating and the effect of the regenerator on the thermal

efficiency.

The working gas used is helium, which has the

advantage of having a low molecular weight and high thermal

conductivity compared to air, allowing a high efficiency system.

Process (1)-(2) is the isothermal compression of the helium at

temperature TC = 50°C, during which

heat QC is rejected to the cooling

water. Process (2)-(3) is the constant volume displacement process

during which heat QR is absorbed from

the regenerator matrix. Process (3)-(4) is the power producing

isothermal expansion process at temperature TE =

500°C, during which heat QE is

absorbed from the gas burner, and finally process (4)-(1) is the

constant volume displacement process during which heat QR

is lost to the regenerator matrix. Thus the ideal

Stirling cycle consists of four distinct processes, each one of which

can be separately analysed in accordance with the methods that are

described in Chapter

3b. State (1) is defined at a maximum

volume of 650 cu.cm and a pressure of 10 bar, and State (2) is

defined at a minimum volume of 550 cu.cm. This large minimum volume

is the dead space due to the unswept volumes including the heater,

regenerator and cooler spaces. (Note

that the values presented here are not actual values of the EG-1000,

however were devised by your instructor for purposes of this exercise

only).

Figure

2. The ideal Stirling cycle engine P-V

diagram

Since the Stirling cycle is a closed cycle, we can

consider each process separately. Thus the work done for each process

can be determined by integration. This is equivalent to evaluating

the area under the P-v curve, as follows:

The working fluid is helium which is an ideal gas, we

use the ideal gas equation of state throughout. Thus P V = m R T,

where R = 2.077 kJ/kg K, and

= CV

= CV

,

where CV = 3.116 kJ/kg K. (refer:

Ideal

Gas Properties)

,

where CV = 3.116 kJ/kg K. (refer:

Ideal

Gas Properties)

a) From the given conditions at state 1 (P = 10

bar = 1000 kPa, V = 650 cc, T = 50°C) determine the mass of working

gas (helium) used in the cycle. [m

= 0.00097 kg (close to 1 gm)]

b) Determine the net work done per cycle

(kiloJoules): WE + WC

(Note that the compression work WC

is always negative). At a frequency of 50 Herz (cycles

per second) determine the power output produced by the engine. [Wnet

= 0.151 kJ/cycle, Power =

7.55 kW]

c) Determine the heat absorbed in the expansion

space QE during the expansion process

(3)-(4). [QE

= 0.260 kJ]

d) Evaluate the Thermal Efficiency

th,

defined as:

th,

defined as:

th

= (WE + WC)

/ QE. (Net mechanical work done

divided by the heat supplied externally by the gas burner). [58

%]

th

= (WE + WC)

/ QE. (Net mechanical work done

divided by the heat supplied externally by the gas burner). [58

%]

e) Determine the amount of thermal power

rejected to the cooling water. Note that at a temperature of 50°C

this is suitable for providing hot water for the home, as well as

providing home space heating capability. [QC

= -0.109 kJ/cycle, Thermal

power to cooling water = 5.45 kW]

f) Determine the amount of heat transferred to

the working fluid QR as it passes

through the regenerator during process (2)-(3). [1.36

kJ] If this heat were to be supplied

externally by the gas burner, (i.e. no regenerator) what would be

the new value of thermal efficiency

th?

[9.3%]

th?

[9.3%]

|

|

In this photograph we see the Sunpower

EG-1000 being demonstrated using sawdust pellets as the fuel, and

generating more than 1000W of electricity to a light panel. This

was done at the Sustainability Fair in the Fairgrounds of Athens

Ohio, 2001. A closeup

photograph of the basic system is

shown. Notice the closed cycle radiator and vibration pump used in

the water cooling system.

|

______________________________________________________________________________________